PREMION|A is a multi-sensor shaft measuring center with which measuring features on rotationally symmetrical workpieces can be measured and documented automatically. Within our advanced measurement technology the PREMION|A is the automated version of the PREMION series. Depending on the created measuring program the test procedure with this shaft measuring device runs completely automatically. Your advantages are high operator independence on the one hand and reproducibility of measurement results on the other hand.

The shaft measuring system PREMION|A therefore replaces a large number of classic manual measuring devices in the production area. Thanks to its modular design and the large selection of equipment PREMION|A can be individualised exactly to your needs.

APPLICATION

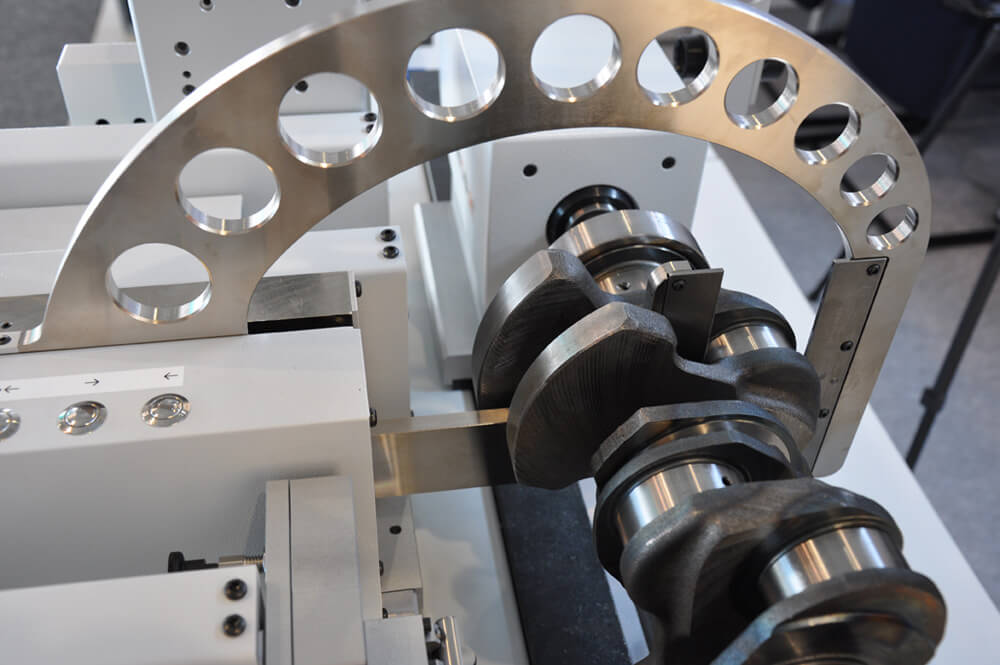

The shaft measuring center PREMION|A allows all measurements on rotationally symmetrical workpieces directly in your manufacture. The advantages are self-evident: the combination of optical and tactile measurements brings you a considerable profit of time in shaft measurement technology and thus a big cost advantage for your company!

CONSTRUCTION

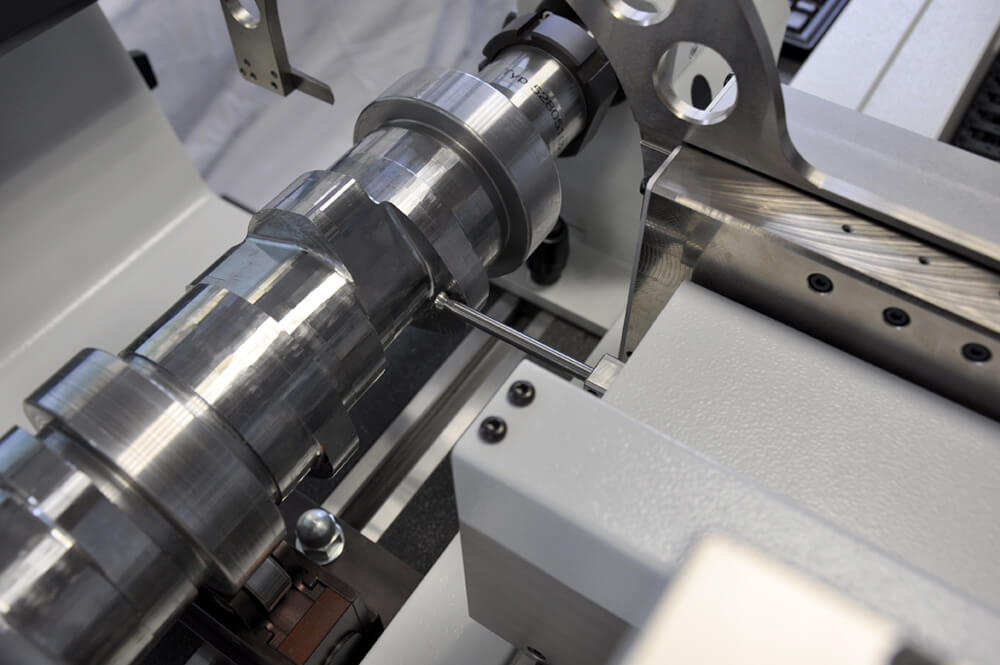

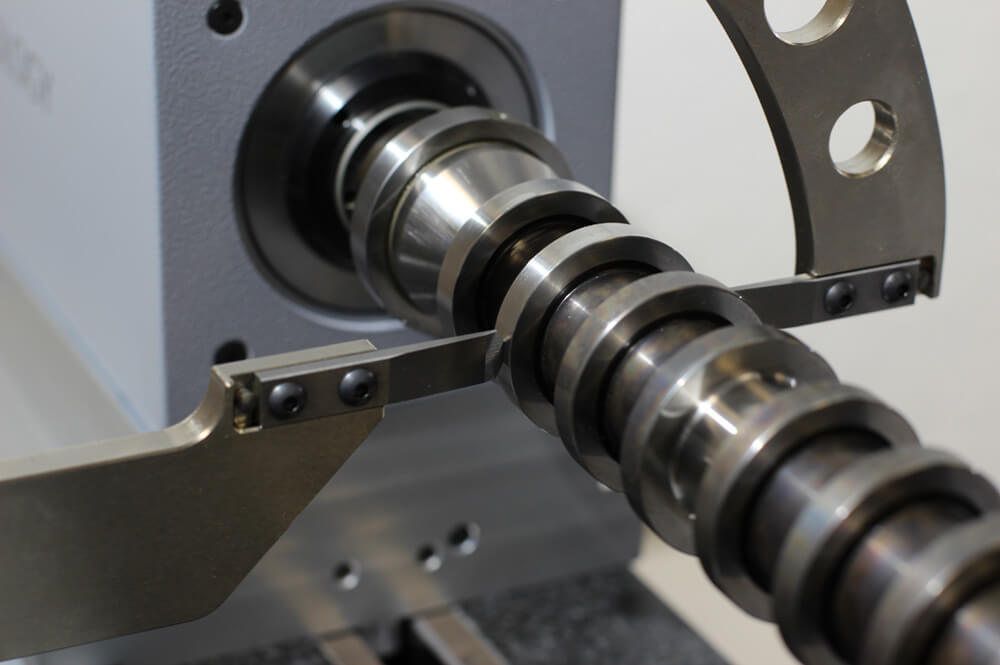

On a stable granite base, the high-precision guides with the driven carriage are mounted. Individually, the different automatic measuring modules are set up on this slide. The workpieces are set with interchangeable tips between the tailstock and the headstock.

HANDLING

The workpiece is clamped between the tips by the system’s operator. The operation works intuitively via touch-screen. All characteristics are measured automatically by the PREMION|A shaft measuring center according to the programmed measuring sequence. The measurement results are displayed on a colored touch-screen, taking into account all possible tolerances. The results are automatically saved in PDF and DFQ format (Q-DAS certified to AQDEF). In addition to automatic operation the PREMION|A may also be operated manually without a certain measuring program. This special feature has great advantages in terms of flexibility in your production.

HIGHLIGHTS

High flexibility of the shaft measuring system due to modular design and a large selection of additional equipment

AQDEF certified software

Easy creation of measuring programs in teach mode

TECHNICAL SPECIFICATIONS

Workpiece dimensions:

Lengths: 400 mm, 800 mm, 1,200 mm

Diameter: 125 mm, 160 mm, 200 mm

Weight: up to 80 kg

MK 2 riding and headstock

PREMION|A modules

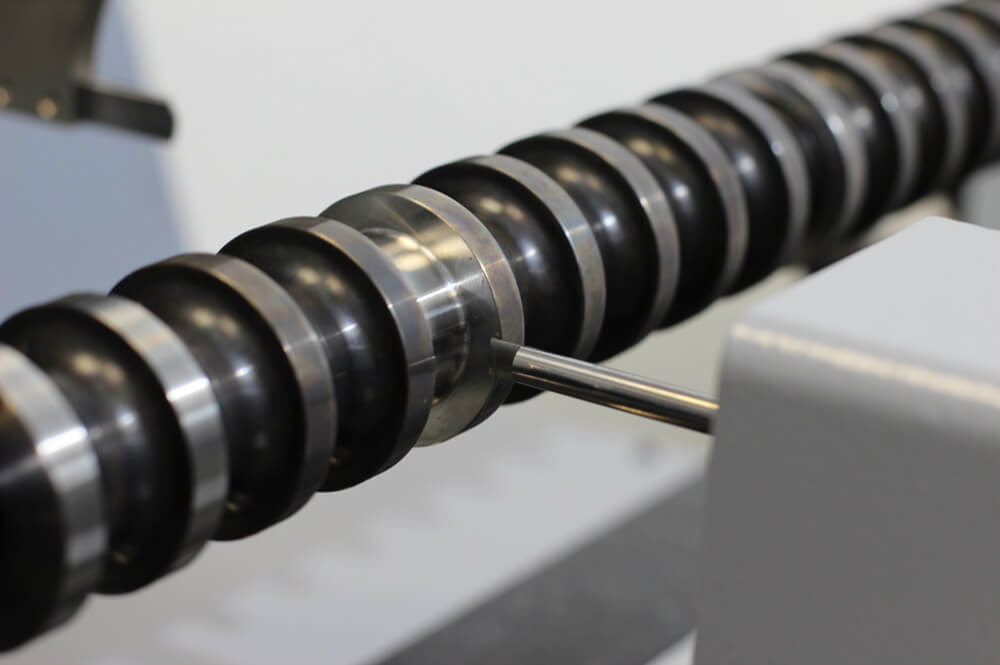

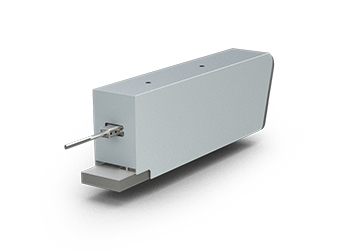

Automatic length module for PREMION|A shaft measuring system

The automatic length module for PREMION | A is flexibly movable radially and axially to the measuring object and additionally provides a shaft measuring system in both axes. By using special and adjustable cross roller guides, the module enables precise and repeatable probing of measuring points. The cross slide allows probing in both directions as well as scanning measurements with this length module as well. Probe elements of our flexible shaft measurement technology may easily be exchanged. The calibration is at once performed on the DAkkS certified center point. When the measuring point is contacted the measured value is recorded by the sensor and displayed on the screen, taking into account pre-specified values and tolerances.

The handling of the axes in this module takes place either automatically via the measuring program or manually by the operator via joystick.

Measurement features: length, distance, center, axial runout, squareness, flatness.

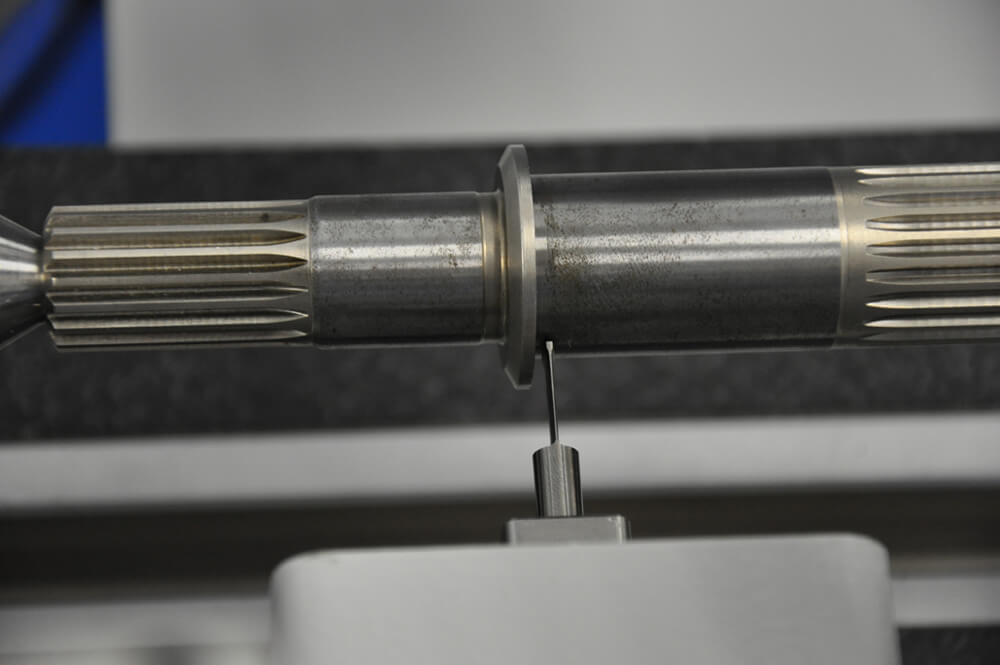

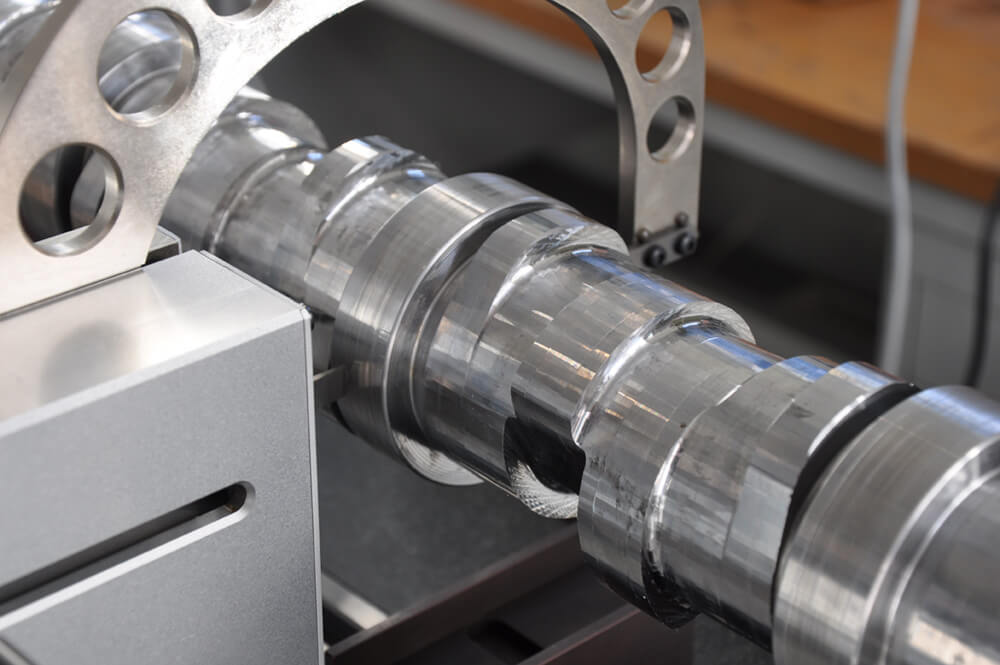

Automatic diameter module for PREMION|A shaft measuring system

The automatic diameter provides two independent measuring systems with opposing probes. These are each located on the bail and rotor of the diameter module. Clump and runner may either work automatically via measuring program or manually by the operator.

This module provides a high-precision bearing on cross roller guides and an advanced spring assembly. This enables the autonomous and reproducible measurement of diameters on rotationally symmetrical workpieces. Measuring according to Abbe’s comparator principle leads to accuracies of <1 μm. Calibration of the measuring module in this diameter module takes place at the DAkkS certified centering point.

Measurement features: diameter, concentricity, roundness, crowning, cylindricity, tip circle diameter, cone angle.

In the version with long probing elements these features can also be determined on connecting rod bearings. In addition to this the stroke radius and the stroke angle are determined as well.

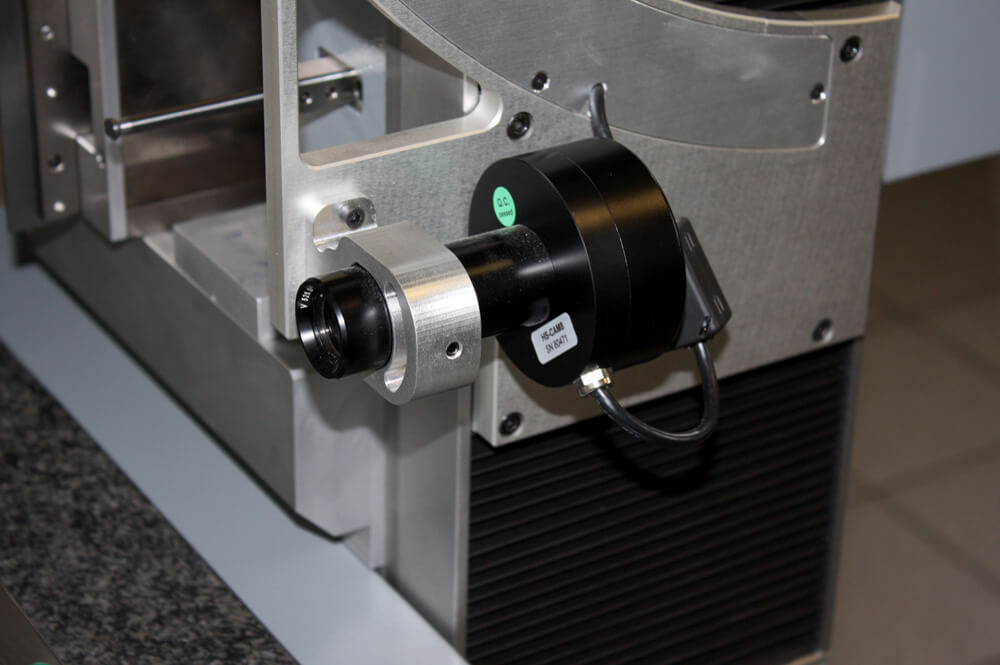

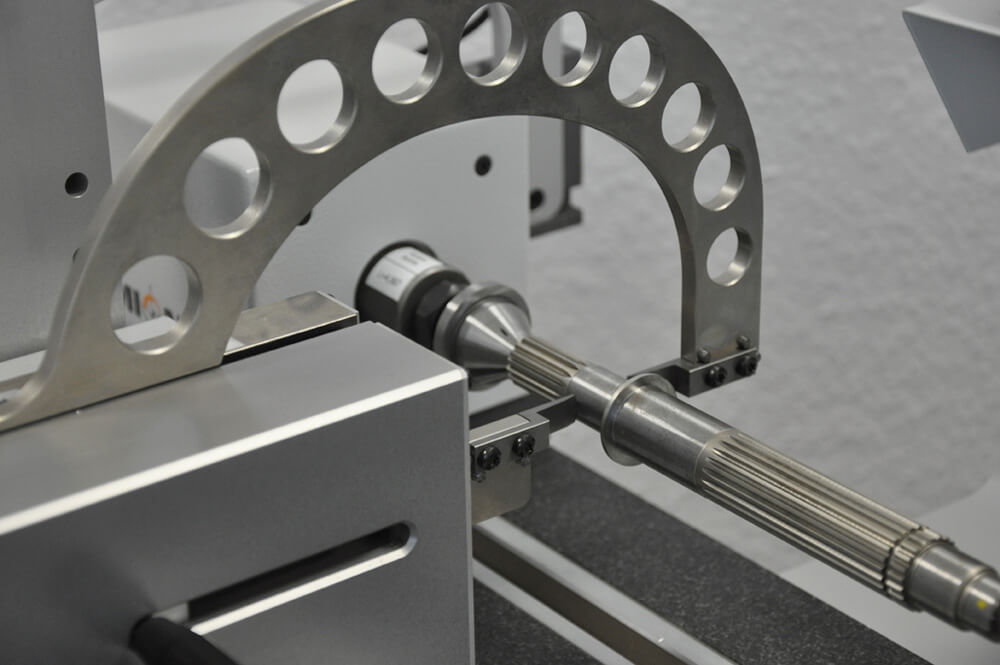

Automatic optical module for PREMION|A shaft measuring system

The automatic optics module comes with a measuring system in the vertical axis. In the transmitted light principle the matrix-camera uses telecentric lenses to detect the contours of the rotationally symmetrical workpieces. When positionined appropiately, the camera directly shows the contour of the component on screen. Furthermore a line, a circle or a crosshair automatically adapt to the contour of the component. Radii, chamfers and other contours can thus be measured quickly, autonomously and repeatable.

The handling of the axis in this module takes place either automatically via the measuring program or manually by the operator via joystick.

Measurement features: chamfer angle, radius, diameter, length, intersection line-line, intersection radius line, intersection radius radius, theoretical intersections, thread pitch.